Brewmatic – Design

I present Brewmatic: a compact, mobile, electric, fully digital, internet connected, voice enabled, 3-stage home brewery.

To read about the motivations behind the beautiful machine, read Brewmatic – Introduction and Problem Statement.

Requirements

The simplified must-haves for Brewmatic:

- Must store within the dimensions of a storage locker that is 74″ tall x 69″ long x 45″ wide.

- Must draw power safely from a single 240V range receptacle.

- Fresh water must be drawn from standard residential taps.

- Waste water must be expelled through standard residential drains.

- Steam must be exhausted to the exterior of the dwelling without condensing and causing leaks inside.

- Must model the traditional 3-stage brewery: Hot Liquor Tank, Mash Tun and Boil Kettle.

- The temperature at each stage of brewing must be controllable and maintainable within 1 degree F.

- Must provide user interfaces through PC, mobile and voice.

High Level Design

- Hot Liquor Tank (HLT)

- Mash Tun (MT)

- Boil Kettle (BK)

- Pumps

- Counter flow wort chiller

- Control unit

- Steam exhaust

- Boil Kettle exhaust lid

- Part storage

- Chemical and glassware storage

- Specialty grain storage

- Grain mill

- Temperature probes

- Drip shelf

- Accessory storage/drying hooks

Brewmatic uses of off-the-shelf components where feasible. In favor of panel mounted PID controllers, as often used in electric breweries, a microcontroller is used with bespoke firmware to reduce cost and space. As a full description of each component would require its own post, a summary of each follows below.

Hardware

Components are mounted on a standard food service wire shelving cart. The first shelf provides storage for parts, grain, mill, oxygen, chemicals, tools and glassware. The second stores hoses, pumps, exhaust vents and the control unit (when not in use). The top shelf primarily acts as a mounting point for the control unit, exhaust venting and brew day accessories.

The third shelf provides a rigid, heat tolerant, and spill proof surface for the heavy (when filled) Hot Liquor Tank (HLT), Mash Tun (MT), and Boil Kettle (BK). An 18-gauge, 304 stainless steel sheet was creased at the edges then welded to the stock wire frame shelf. These edges keep spilled liquid from cascading down to the lower shelves (a hard lesson). The sheet also greatly increases the strength of the shelf. Without it, a full pot dramatically warps the wire shelf downwards, so much that it is difficult to take liquid readings from the pot’s inside markings.

All metal hardware (pots, tubing, fitting, couplers, valves, etc.) is 304 stainless steel. All three pots are fitted with PT100 temperature probes and ball valves.

Hot Liquor Tank – 15 Gallons

A 25ft steel coil exchanges heat between hot water inside the pot and wort recirculating to/from the MT. A stainless hot water tank heating element provides direct contact heat. The HLT is “stirred” using recirculation to maintain a uniform temperature. Water is pumped from the valve at the pot’s bottom to the right angle tube mounted at the top.

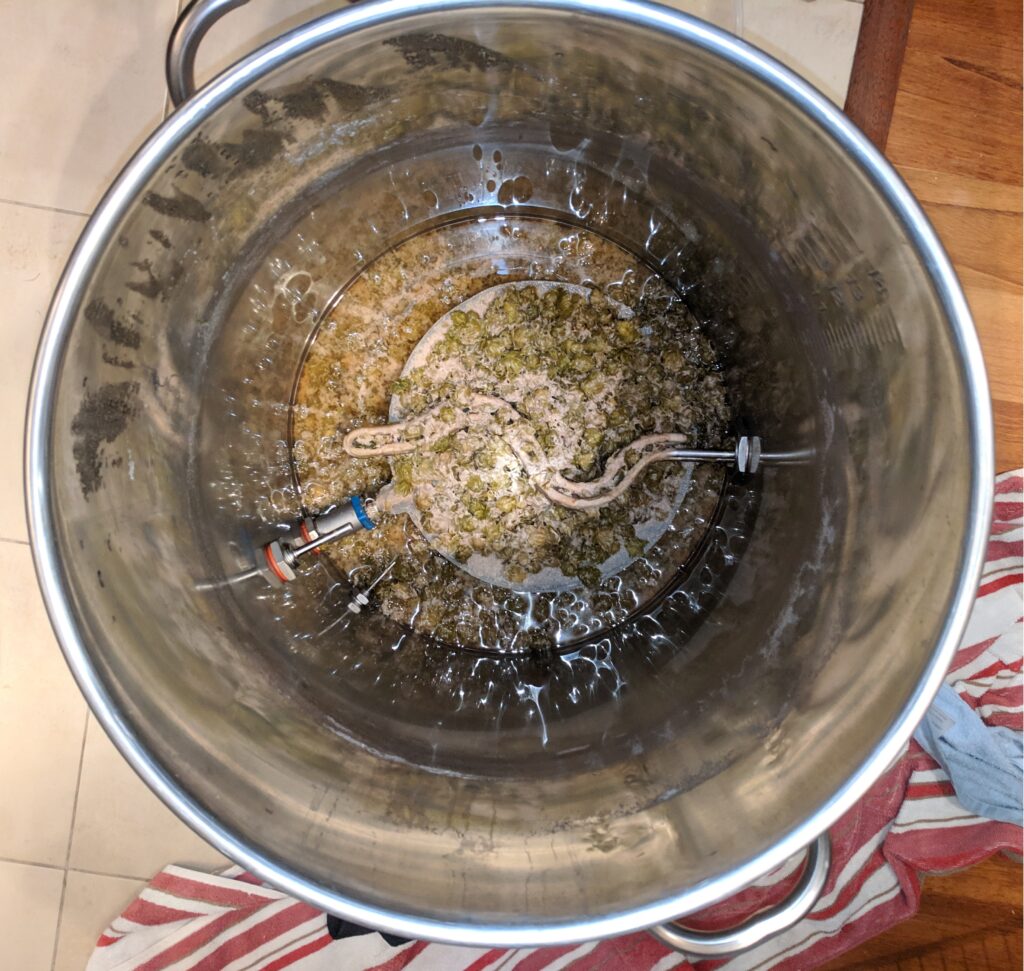

Mash Tun – 10 Gallons

A Blichmann AutoSparge is used to control recirculation rates during the sparge. It was necessary to down size the MT from 15 gallons (pictured at top of post) to 10 for reliable control over the liquid level above the grain bed. If the pot is too large, more liquid is required to keep the grain bed below the surface than is optimal. The AutoSparge needs enough head room to float and perform properly.

A standard convex, perforated, steel plate provides the false bottom.

Boil Kettle – 15 gallons

A stainless “pancake” filter sits below another stainless hot water tank heating element. Inside the pancake filter is a stainless straw, bent slightly, and pointed towards the bottom of the pot to minimize dead space.

Plumbing

1/2″ camlock couplers are used between all hose connections. 1/2″ silicon tubing is used for all liquids, with the exception of fresh water. This is braid reinforced PVC for connection (also camlock) to a high pressure household water faucet. Two Blichmann RipTide pumps are used to transfer/recirculate between the HLT/MT and MT/BK. Cooling is accomplished using a 25ft counter-flow wort chiller and tap water.

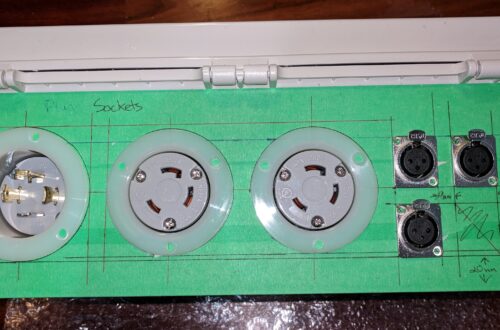

Electrical

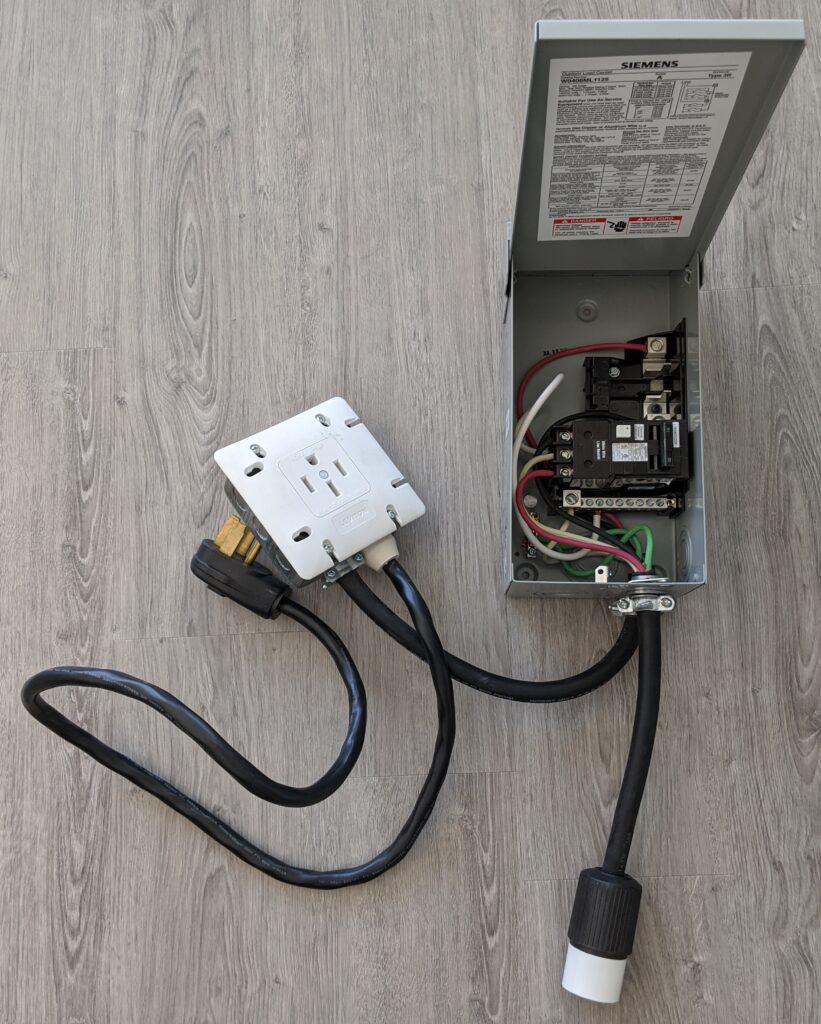

The only 240V source available in the unit is from the range (stove). I couldn’t find anything off-the-shelf that converts a range outlet to a 4 wire GFCI. So I built one with a spa panel (Siemens) from Costco, a NEMA 14-50R from Home Depot and a NEMA L6-30R from Amazon. The beauty of this solution is the ability to keep the stove plugged in.

This powers the heating elements (240VAC) in the HLT and MT, pumps (120VAC) and control circuitry (3/5VDC).

Control

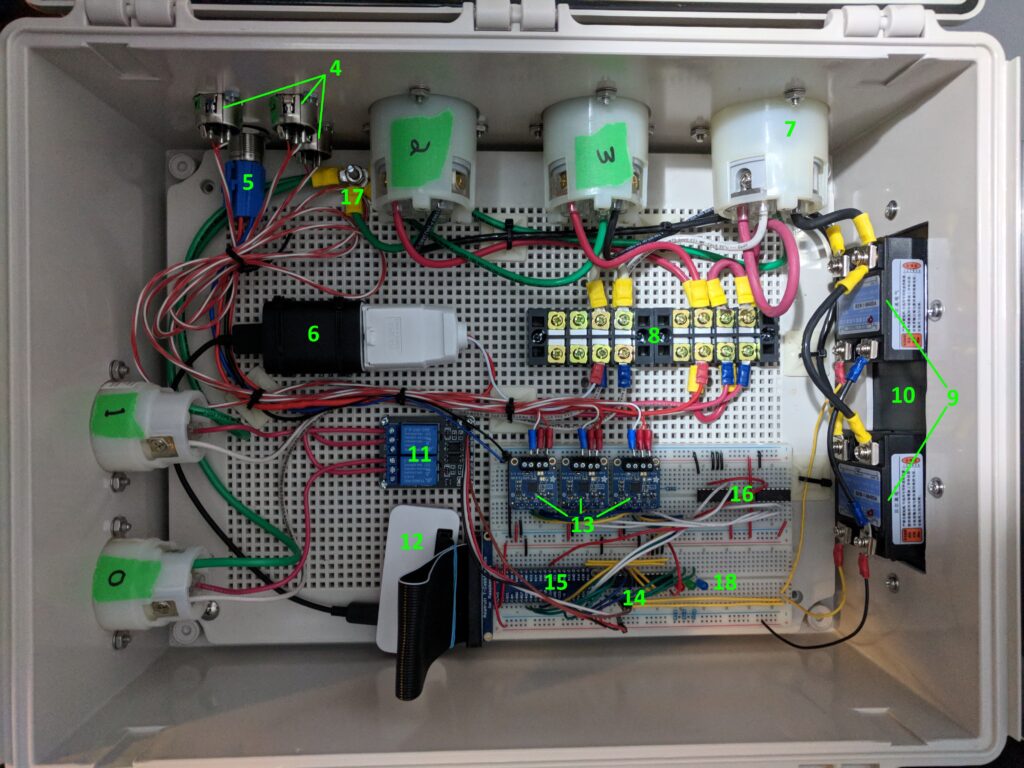

Digital control of the system is handled by a Raspberry Pi Zero (12, see Firmware below). Pulse-width modulation controls the duty cycle of the heating elements (2, 3) via solid-state relays (9). Temperature for each of the HLT, MT and BK are read through PT100 sensors (4) connected to the I2C bus (13). Automotive relays (11) provide control of the pumps.

- Hot Liquor Tank Pump 120V out receptacle

- Mast Tun Pump 120V out receptacle

- Hot Liquor Tank 240V out receptacle

- Boil Kettle 240V out receptacle

- Temperature probe receptables

- Master power switch

- 120VAC to 5VDC converter

- 240VAC in receptacle

- 120VAC bus bars

- Boil Kettle/Hot Liquor Tank solid state relays

- Heat sink

- Pump relays

- Raspberry Pi Zero

- PT100 drivers

- I/O multiplexing logic

- Raspberry Pi I/O expander

- Safety logic, prevents activating both solid state relays simultaneously

- Common ground

- Debug LEDs

Firmware

A C++ driver performs the following basic input/output functions:

- Toggle pumps on/off

- Heating element power (in percent) via pulse width modulation

- Read temperature probes

This driver is used by a multi-threaded Python application to control the system in response to commands from the user via the cloud. The application reports changes in state back to the cloud for user visibility. For example: confirmation that HLT pump is on, or temperature changes while the HLT is heating up.

The C++/Python split was chosen for rapid development and testing. The Pi Zero is quite capable of running Python code without becoming resource constrained.

Cloud

Cloud infrastructure is hosted on AWS. IoT device shadows are used to communicate state/settings to/from the device and the user interface. The IoT Python SDK makes it easy to integrate secure communication on the Pi Zero.

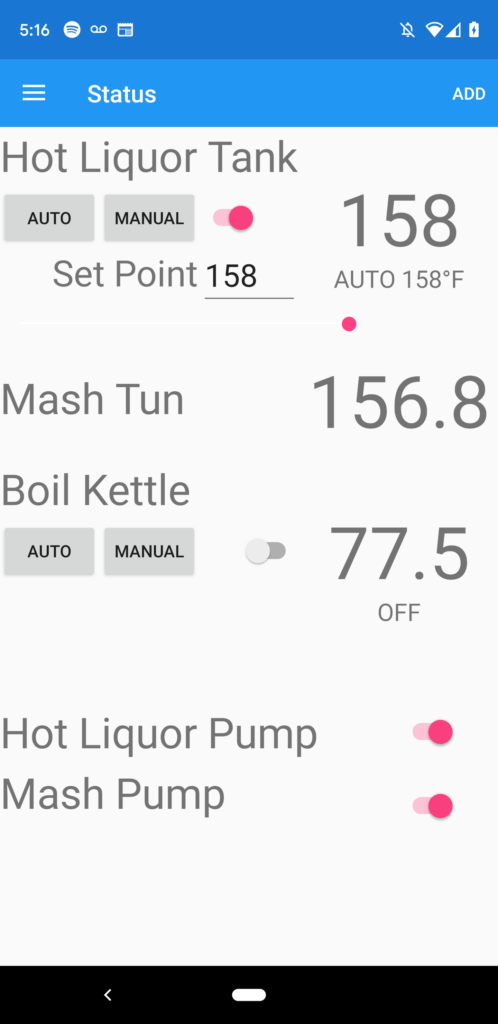

Visual User Interface

Xamarin was selected as the UI framework for the following reasons:

- I didn’t want to write separate iOS and Android code.

- Xamarin provides a Windows UI (bonus).

- There is some support for the AWS IoT SDK.

- I wanted to re-learn C#.

The UI renders well on all of Windows, iOS and Android.

Voice User Interface

Using AWS as a cloud provider made it easy to develop an Alexa Skill to control the system verbally. Also, I happened to work in Alexa, writing a skills SDK, at the time.

The voice interface lets a user query for temperature of the HLT, MT or BK. They can also turn on pumps or change the set point of the HLT or BK. This is extremely helpful when the brewers hands are busy, which is always!

2,132 Comments

Tools For Creators

I am really inspired along with your writing talents and also with the format for your weblog. Is that this a paid subject or did you modify it yourself? Anyway stay up the nice quality writing, it’s uncommon to look a nice weblog like this one nowadays. !

TestUser

seshtFIN xZYZuC FLgFr

TestUser

McVLy fpnn VoPVyvf ZioTEGHx wYhPubf wcqKlTuk

John

tNmS qthnZw cxC vMRo ySmSgyT QIWWFku

Christian1715

http://passo.su/forums/index.php?autocom=gallery&req=si&img=4159

Alaina2104

https://mazda-demio.ru/forums/index.php?autocom=gallery&req=si&img=6414

Donald2341

Very good https://is.gd/tpjNyL

TommymuB

hi

Jocelyn436

https://myteana.ru/forums/index.php?autocom=gallery&req=si&img=6819

Bella4186

https://honda-fit.ru/forums/index.php?autocom=gallery&req=si&img=7236

Jed2076

https://vitz.ru/forums/index.php?autocom=gallery&req=si&img=4814

Gretchen3339

https://myteana.ru/forums/index.php?autocom=gallery&req=si&img=6763

Clara4614

https://myteana.ru/forums/index.php?autocom=gallery&req=si&img=6747

Angelo3642

https://myteana.ru/forums/index.php?autocom=gallery&req=si&img=6787

Emilie58

https://honda-fit.ru/forums/index.php?autocom=gallery&req=si&img=7200

Derrick594

http://wish-club.ru/forums/index.php?autocom=gallery&req=si&img=5345

Veronica409

http://terios2.ru/forums/index.php?autocom=gallery&req=si&img=4677

Clint2245

https://mazda-demio.ru/forums/index.php?autocom=gallery&req=si&img=6474

Laura4869

https://honda-fit.ru/forums/index.php?autocom=gallery&req=si&img=7081

Lauryn1807

https://vitz.ru/forums/index.php?autocom=gallery&req=si&img=4863

Emilie2555

https://myteana.ru/forums/index.php?autocom=gallery&req=si&img=6666

xmc.pl

Reading your post is like a journey through a picturesque landscape of thought – full of color, depth, and light! If you ever decide to publish a book, you’ll surely find a devoted audience waiting for it!

Charlesitede

Hello,

Exclusive promo quality music for DJs https://sceneflac.blogspot.com

MP3/FLAC, label, music videos. Fans giving you full access to exclusive electronic, rap, rock, trance, dance… music.

0day team.

Jimmy1720

https://hrv-club.ru/forums/index.php?autocom=gallery&req=si&img=7168

Adria1352

http://wish-club.ru/forums/index.php?autocom=gallery&req=si&img=5249

Harrison1283

https://vitz.ru/forums/index.php?autocom=gallery&req=si&img=4838

Lynne3792

https://myteana.ru/forums/index.php?autocom=gallery&req=si&img=6659

Aniya3607

http://passo.su/forums/index.php?autocom=gallery&req=si&img=4283

Maggie929

Tanir & Tyomcha – Да Да Да скачать песню и слушать бесплатно https://shorturl.fm/NnM4W

Kingston1288

Anton Verkhotin & Антон Верхотин – Загрустила скачать песню и слушать бесплатно https://shorturl.fm/YGtey

Hailey994

The Коля – Идивжнапмж скачать и слушать песню https://shorturl.fm/PFLTA

Cara1697

Вика Воронина – Зажигай, Детка! скачать песню и слушать онлайн https://shorturl.fm/OYe6v

Katelyn3724

ФОГЕЛЬ – ПУЛЯ скачать и слушать песню https://shorturl.fm/Mh9SJ

Kenny2531

Gidayyat & Gazan – Коронаминус скачать песню в mp3 и слушать онлайн https://shorturl.fm/PDWO7

Anastasia4571

Marina – Кино скачать mp3 и слушать бесплатно https://shorturl.fm/we49t

Harry99

Егор Крид, The Limba – Coco L’Eau скачать песню и слушать бесплатно https://shorturl.fm/a2G6Q

Elijah3570

Мот – Перемены-это красиво скачать песню и слушать бесплатно https://shorturl.fm/sc09i

sxpksgyfhw

qlmkhuueoeslntnfmikyxepgmyomfo

jnpljtztqj

zsxlqrowwkvhfeqervjifmwkikmoyk

📈 Email; Process 1,236437 BTC. Confirm => https://yandex.com/poll/7R6WLNFoDWh6Mnt8ZoUfWA?hs=5ff75b51b205032386e9a0ddf68362c3& 📈

tr4b34

Ivan2608

https://mazda-demio.ru/forums/index.php?autocom=gallery&req=si&img=6528

Angelo4904

https://hrv-club.ru/forums/index.php?autocom=gallery&req=si&img=6904

Zane2543

https://vitz.ru/forums/index.php?autocom=gallery&req=si&img=4939

Kate4330

https://myteana.ru/forums/index.php?autocom=gallery&req=si&img=6605

Lynn1903

https://mazda-demio.ru/forums/index.php?autocom=gallery&req=si&img=6552

Emory1812

https://vitz.ru/forums/index.php?autocom=gallery&req=si&img=5012

Greta4712

Asammuell – До Встречи скачать песню в mp3 и слушать онлайн https://shorturl.fm/4tz5S

Sydney1266

Гуф, Мари Краймбрери – 31 февраля скачать бесплатно и слушать онлайн https://shorturl.fm/xRDEj

Kaylee1811

84 feat. Lookbuffalo – Газировка скачать бесплатно mp3 и слушать онлайн https://shorturl.fm/F9IQO

Sandra842

Султан Лагучев – Любовь-Беда скачать и слушать песню бесплатно https://shorturl.fm/dymGY

Whitney3363

Валерий Шаповалов и группа Лимонадный Джо – Весело живем скачать песню и слушать онлайн https://shorturl.fm/K5lSb

Braxton1229

VA – Пьян скачать mp3 и слушать онлайн бесплатно https://shorturl.fm/aGLFS

Hanna3257

Гио Пиkа Feat. & Кравц – Тупая Боль (Adam Maniac Remix) скачать и слушать онлайн https://shorturl.fm/hBnCV

Allan2787

Рельсы – Во Сне скачать песню и слушать бесплатно https://shorturl.fm/EonST

Hello

OKtIYAce wTkz ZGnKsq

augmentin sleeplessness

will augmentin treat pneumonia Analysis for enrichment of DMFS associated genes

Dylan367

Каролина – Зимний вечер скачать песню и слушать онлайн

https://allmp3.pro/2373-karolina-zimnij-vecher.html

Micah4767

Юрий Шатунов – Майский вечер (MegaSound & DJ BARS Remix) скачать песню и слушать онлайн

https://allmp3.pro/3208-jurij-shatunov-majskij-vecher-megasound-dj-bars-remix.html

Brylee2279

Hollyflame – Плевать скачать песню и слушать онлайн

https://allmp3.pro/3243-hollyflame-plevat.html

Leanne3414

Даша Волосевич – Парашют скачать песню и слушать онлайн

https://allmp3.pro/3324-dasha-volosevich-parashjut.html

Campbell967

Karenchik – Ты Больна скачать песню и слушать онлайн

https://allmp3.pro/3247-karenchik-ty-bolna.html

Amelie3922

Костя Boomer – Пилю Колодки скачать песню и слушать онлайн

https://allmp3.pro/2961-kostja-boomer-pilju-kolodki.html

Fiona3828

Скачков – Этой Ночью 2 (LVDIZZY Remix) скачать песню и слушать онлайн

https://allmp3.pro/2951-skachkov-jetoj-nochju-2-lvdizzy-remix.html

Peter3488

Alex Coffman Feat. & Paperwhale – Как Было Бы Здорово скачать песню и слушать онлайн

https://allmp3.pro/2858-alex-coffman-feat-paperwhale-kak-bylo-by-zdorovo.html

Maya4034

Гузель Хасанова – Черно белый скачать песню и слушать онлайн

https://allmp3.pro/2582-guzel-hasanova-cherno-belyj.html

Sabrina4917

5sta Family – Вместе Мы (Sasha First Radio Remix) скачать песню и слушать онлайн

https://allmp3.pro/3136-5sta-family-vmeste-my-sasha-first-radio-remix.html

djgfswnpfn

xehfwhghftfgmhwilrjdzyflmpmvml

reneheage

Восстановление бампера автомобиля — это популярная услуга, которая позволяет вернуть заводской вид транспортного средства после незначительных повреждений. Современные технологии позволяют исправить потертости, трещины и вмятины без полной замены детали. При выборе между ремонтом или заменой бампера https://telegra.ph/Remont-ili-zamena-bampera-05-22 важно учитывать степень повреждений и экономическую выгодность. Экспертное восстановление включает подготовку, грунтовку и покраску.

Замена бампера требуется при критических повреждениях, когда восстановление бамперов невыгоден или невозможен. Цена восстановления варьируется от состава изделия, характера повреждений и типа автомобиля. Пластиковые элементы подлежат ремонту лучше железных, а современные композитные материалы требуют профессионального оборудования. Грамотный ремонт расширяет срок службы детали и поддерживает заводскую геометрию кузова.

Рад был бы предложить содействие по вопросам Бампер рено логан передний ремонт – стучите в Телеграм daa39

Психоаналитик это психотерапевт практикующий психоанализ

Психоаналитик это психотерапевт практикующий психоанализ Психоаналитик это психотерапевт практикующий психоанализ 428

reneheage

Восстановление бампера автомобиля — это популярная услуга, которая позволяет вернуть первоначальный вид транспортного средства после небольших повреждений. Передовые технологии позволяют убрать царапины, трещины и вмятины без полной замены детали. При выборе между ремонтом или заменой бампера https://telegra.ph/Remont-ili-zamena-bampera-05-22 важно принимать во внимание масштаб повреждений и экономическую выгодность. Профессиональное восстановление включает шпатлевку, грунтовку и покраску.

Смена бампера требуется при критических повреждениях, когда ремонт бамперов невыгоден или невозможен. Цена восстановления варьируется от типа материала изделия, характера повреждений и марки автомобиля. Полимерные элементы поддаются ремонту лучше железных, а инновационные композитные материалы требуют специального оборудования. Грамотный ремонт расширяет срок службы детали и сохраняет заводскую геометрию кузова.

Охотно окажу содействие, при возникновении необходимости по вопросам Ремонт бамперов цены воронеж – пишите в Telegram bou88

Tobiasnenue

Hello,

Club music download FTP, quality music https://0daymusic.org

MP3/FLAC, label, music videos, soft, nfo. Fans giving you full access to exclusive electronic, rap, rock, trance, dance… music.

0day team.

uorguhlouh

ypwkwfkpklxevejumytoyptjkfilhy

best THC gummies

Good shout.

full spectrum cbd gummies

full spectrum cbd gummies area 52

weed pen

weed pen area 52

thc gummies

thc gummies

distillate carts

distillate carts area 52

infused pre rolls

infused pre rolls area 52

liquid thc

liquid thc area 52

thca gummies

thca gummies area 52

live resin gummies

live resin gummies area 52

best amanita edibles

best amanita edibles area 52

indica gummies

indica gummies area 52

indica vape

indica vape area 52

live rosin gummies

live rosin gummies area 52

sativa gummies

sativa gummies area 52

best thca flower

best thca flower area 52

magic mushrooms for sale

magic mushrooms for sale area 52

thc tinctures

thc tinctures area 52

buy pre rolls online

buy pre rolls online area 52

live resin

live resin area 52

1 gram carts

1 gram carts area 52

snow caps weed

snow caps weed area 52

thca disposable

thca disposable area 52

thc oil

thc oil area 52

CharlesRib

Planning your next adventure? Let ItaliaRail be your trusted companion for seamless travel across Italy

and beyond!

With our easy booking platform, you’ll find the best routes, competitive prices,

and real-time updates—making your trip as smooth as the scenic landscapes outside your window.

Whether you’re exploring the romantic canals of Venice, the historic streets of Rome,

or venturing further across Europe, we ensure comfort, reliability, and unforgettable experiences.

Why choose ItaliaRail? Enjoy exclusive benefits like flexible tickets, 24/7 customer support,

and special discounts for frequent travelers. Skip the hassle and travel smarter—your dream getaway

is just a click away. Book with ItaliaRail today and let the journey inspire you!

zephyr car

lychee sorbet ace ultra premium

Nice

weed pen

OS

CBD Gummies 2025: Best CBD Gummies for Pain Anxiety & Sleep

RQ

thc gummies for anxiety

thc gummies for anxiety area 52

thc microdose gummies

thc microdose gummies area 52

thc gummies for pain

thc gummies for pain area 52

live resin carts

live resin carts area 52

thc sleep gummies

thc sleep gummies area 52

best disposable vaporizers

best disposable vaporizers area 52

hybrid carts

hybrid carts area 52

buy thca

buy thca area 52

liquid diamonds

liquid diamonds area 52

thca diamonds

thca diamonds area 52

thcv gummies

thcv gummies area 52

thc vape

thc vape area 52

hybrid gummies

hybrid gummies area 52

Sutitdsmake

Looking for the official Betandreas casino platform in Bangladesh? Visit https://betandreasx.com/ and you will find all the details and detailed information from this casino. Find out all the benefits on the site – from a huge selection of games, convenient registration, deposit and withdrawal of money, as well as all about the platform bonuses.

Loracunams

Оазис в Сочи https://eromassage-sochi.ru/ – Погружение в мир эротического массажа. Мечтаете о полном расслаблении и ярких эмоциях? Салон “Оазис” в Сочи приглашает вас в уникальное путешествие чувственности. Опытные массажистки, владеющие искусством эротического массажа, создадут для вас атмосферу уединения и блаженства. Забудьте о повседневности, доверьтесь нашим рукам и откройте новые грани наслаждения. Мы гарантируем полную конфиденциальность и индивидуальный подход. Откройте свой Оазис в Сочи, где каждый прикосновение – это источник удовольствия.

ThomasDen

https://t.me/s/Web_1win

ThomasDen

https://t.me/s/Webs_1WIN

ThomasDen

?? 1win: твоя победа начинается здесь! ??

Всем привет, дорогие друзья и подписчики 1win! Мы рады приветствовать вас на нашем канале, где вас ждут свежие новости из мира спорта и киберспорта, а также выгодные бонусы и акции от вашей любимой букмекерской конторы.

Почему выбирают 1win?

1win — это не просто букмекерская контора. Это целая платформа развлечений, где каждый найдет что-то для себя. Вот лишь несколько причин, по которым стоит выбрать 1win:

Широкий выбор ставок: мы предлагаем ставки на все популярные виды спорта, от футбола и хоккея до тенниса и баскетбола. А также на киберспорт — Dota 2, CS:GO, League of Legends и многое другое!

Выгодные коэффициенты: мы стремимся предлагать самые конкурентоспособные коэффициенты на рынке, чтобы ваша победа принесла вам ещё больше выгоды.

Щедрые бонусы: новые игроки получают приветственный бонус до 500 % на первый депозит! Кроме того, мы регулярно проводим акции и разыгрываем ценные призы.

Удобный интерфейс: наш сайт и мобильное приложение интуитивно понятны и просты в использовании, что позволяет делать ставки быстро и удобно.

Круглосуточная поддержка: наша служба поддержки всегда готова помочь вам с любыми вопросами.

Новости и акции 1win:

?? Бонус за экспресс! Собирайте экспрессы из 5 и более событий и получайте дополнительный бонус к выигрышу! Чем больше событий, тем больше бонус!

?? Специальные предложения на топовые футбольные матчи! Следите за нашими анонсами и не пропустите повышенные коэффициенты и специальные акции на самые интересные футбольные матчи недели.

?? Турниры по киберспорту с призовым фондом! Участвуйте в наших турнирах и боритесь за ценные призы и признание.

Как начать выигрывать с 1win?

Зарегистрируйтесь на сайте или в приложении 1win: Это займёт всего несколько минут!

Внесите депозит: Воспользуйтесь удобным для вас способом пополнения счета.

Выберите интересующее вас событие и сделайте ставку: Начните выигрывать прямо сейчас!

Не упустите свой шанс! Подписывайтесь на наш канал и будьте в курсе всех самых свежих новостей и акций 1win!

#1win #ставки #спорт #киберспорт #бонусы #акции #победа #выигрыш

Почему это хорошо для индексации в Яндексе:

Ключевые слова: В тексте используются такие ключевые слова, как «1win», «ставки», «спорт», «киберспорт», «бонусы», «акции», «победа», «выигрыш», которые пользователи ищут в Яндексе.

Заголовки и подзаголовки: Четкая структура с заголовками и подзаголовками облегчает сканирование текста поисковым роботом.

Релевантность: Текст соответствует тематике канала 1win и содержит полезную информацию для потенциальных пользователей.

Хэштеги: Использование хэштегов повышает видимость публикации в поисковой выдаче Яндекса.

Активность: Призыв подписаться и принять участие в акциях стимулирует взаимодействие с контентом, что положительно сказывается на ранжировании.

Дополнительные советы:

Регулярно публикуйте контент: чем чаще вы публикуете новые интересные материалы, тем лучше они индексируются поисковыми системами.

Используйте изображения и видео: Визуальный контент привлекает больше внимания и делает ваши публикации более интересными.

Взаимодействуйте с подписчиками: отвечайте на комментарии и вопросы, проводите опросы и конкурсы.

нашем телеграм канал:https://t.me/s/official_1win_rus

Удачи! И пусть удача всегда будет на вашей стороне с 1win!

промокод на 1win

https://t.me/s/Webs_1win

ThomasDen

https://t.me/s/B43_1WIN/23

guaezaalke

https://guage.tools/

1WIN

Официальный Telegram канал 1win Casinо. Казинo и ставки от 1вин. Фриспины, актуальное зеркало официального сайта 1 win. Регистрируйся в ван вин, соверши вход в один вин, получай бонус используя промокод и начните играть на реальные деньги.

https://t.me/s/Official_1win_kanal/5121

AndresTok

https://t.me/s/Officiall_Telegram_1win

Dichaeljew

Wow that was unusual. I just wrote an incredibly long comment but after I clicked submit my comment didn’t show up. Grrrr… well I’m not writing all that over again. Anyways, just wanted to say great blog!

https://reklama-sev.com.ua/fary-shcho-yak-novi-sekret-u-prostij-detali.html

EmmaHenia

Hey, I just stumbled onto your site… are you always this good at catching attention, or did you make it just for me? Write to me on this website — rb.gy/3pma6x?Henia — my username is the same, I’ll be waiting.

google analytics alternative

Google Analytics Alternative

WilliamOxirm

категории swot анализа swot анализ позволяет

advokat_rrsa

Сегодня юридические услуги необходимы как никогда. Каждый может столкнуться с правовыми вопросами, которые требуют профессионального вмешательства..

Сайт konsultaciya-advokata11.ru предоставляет разнообразные юридические услуги.. На нашем сайте доступны услуги по самым разным направлениям права. Получите помощь квалифицированного юриста на юридическая помощь онлайн бесплатно россия круглосуточно.

Квалифицированные юристы окажут необходимую помощь в любой ситуации. Мы стремимся предоставить клиентам только лучшие юридические решения..

Воспользуйтесь нашими услугами, и вы останетесь удовлетворены результатом.. Каждая консультация осуществляется с учетом ваших потребностей и обстоятельств.

Free chat via Uhmegle

Die Verbindung auf dieser Plattform ist stabil und läuft ohne Unterbrechung.

Join Uhmegle free now

Schon nach wenigen Sekunden hatte ich interessante Gespräche auf Uhmegle.

Free chat via Uhmegle

I’ve already recommended Uhmegle.org to a couple of friends. They also said it feels faster and more reliable compared to other platforms.

Enter the chat at Uhmegle

I was curious about alternatives and found this great read: Best Omegle Alternatives 2025. Worth checking!

Enter uhmegl today

Conocer gente nueva aquí: Uhmegle.

Go to random chat site

Commencez à chatter après le téléchargement.

konsultaci_fhPi

Получите бесплатную юридическую консультацию онлайн, чтобы оперативно решить все ваши юридические вопросы!

Мы предлагаем консультации по множественным направлениям права.

yuridiches_pqOr

Обратитесь за помощью к профессионалам на помощь юриста бесплатно по телефону москва, и получите квалифицированное решение своих вопросов.

ресурс yuridicheskaya-konsultaciya34.ru предлагает профессиональные юридические услуги, направленные на решение различных правовых вопросов. Команда опытных юристов готова помочь вам в самых сложных ситуациях. Мы понимаем, что правовые проблемы могут быть стрессовыми, мы предлагаем внимательное отношение к каждому клиенту.

Мы предлагаем широкий спектр услуг, включая консультации по гражданским и уголовным делам. Настоятельно рекомендуем связаться с нами по вопросам, связанным с трудовым правом, семейными делами и другими юридическими аспектами. Мы понимаем, что каждая ситуация требует индивидуального подхода, и готовы предложить оптимальное решение.

Мы зарекомендовали себя как надежный партнер в сфере юриспруденции. Мы получаем положительные отзывы от клиентов за высокое качество обслуживания и результативность. Каждый юрист нашей команды имеет опыт работы в различных областях права и готов поддержать вас в любое время.

Обращайтесь к нам уже сегодня, чтобы получить квалифицированную юридическую помощь. Мы готовы ответить на все ваши вопросы . Воспользуйтесь нашими услугами на yuridicheskaya-konsultaciya34.ru.

montenegro-65

Mochten Sie ein https://www.immobilien-in-montenegro-fuer-oesterreicher.com kaufen? Tolle Angebote am Meer und in den Bergen. Gro?e Auswahl an Immobilien, Unterstutzung bei der Immobilienauswahl, Transaktionsunterstutzung und Registrierung. Leben Sie in einem Land mit mildem Klima und wunderschoner Natur.

dnscompetition-371

best articles on the net: https://dnscompetition.in/pa/articles/dns-and-machine-learning-optimizing-traffic-management/

porno-819

Want to have fun? hack apk Watch porn, buy heroin or ecstasy. Pick up whores or buy marijuana. Come in, we’re waiting

promocod-iherb-872

Новые актуальные iherb промокод для новых для выгодных покупок! Скидки на витамины, БАДы, косметику и товары для здоровья. Экономьте до 30% на заказах, используйте проверенные купоны и наслаждайтесь выгодным шопингом.

shponirovanie-265

шпонированная дсп шпонирование цена

geodezicheskie-izyskaniya-186

вызов геодезиста услуги геодезиста цены

geotekstil-719

геотекстиль сибур геотекстиль для отмостки цена

minprom-info-257

Включение в реестр Минпромторга https://minprom-info.ru официальный путь для подтверждения отечественного производства. Подготовка и подача документов, юридическое сопровождение и консультации для производителей.

craftsmm-290

Платформа онлайн-обучения https://craftsmm.ru курсы по маркетингу, продажам и рекламе для новичков и профессионалов. Освойте современные инструменты продвижения, увеличьте продажи и развивайте карьеру в удобном формате.

vasdiplom-378

Написание дипломов на заказ https://vasdiplom.ru помощь студентам в подготовке итоговых работ. Авторские тексты, проверка на уникальность и полное соответствие стандартам учебных заведений.

drugs-142

Want to have fun? porno egypt melbet Whores, drugs, casino. We have it all, any drugs are on sale.

porno-876

купить амфетамин меф спайс волгоград купить героин в шарье

uofs-beslan-866

Обучение и семинары https://uofs-beslan.ru для профессионалов: современные программы, практические кейсы и опыт экспертов. Развивайте навыки, повышайте квалификацию и получайте новые возможности для карьерного роста.

Charlestot

Лицей взаимного обучения https://talgenisty.ru уникальная среда для детей и взрослых. Совместные уроки, обмен опытом, мастер-классы и творческие проекты. Образование, основанное на поддержке и сотрудничестве.

tatyanamostseeva-888

Школа видеорекламы https://tatyanamostseeva.ru обучение созданию креативных роликов для бизнеса и брендов. Практические занятия, работа с современными инструментами и поддержка экспертов. Освойте профессию в сфере digital.

RonnieBix

Нужен автобусный билет? билеты на автобус удобный сервис поиска и бронирования. Широкий выбор направлений, надежные перевозчики, доступные цены и моментальная отправка электронных билетов на почту.

OrlandoHog

Авто портал https://diesel.kyiv.ua все о мире автомобилей: новости, обзоры моделей, тест-драйвы, советы по выбору и уходу за авто. Каталог машин, актуальные цены, автоуслуги и полезная информация для автовладельцев.

BillyDrign

Все для автомобилистов https://k-moto.com.ua на авто портале: новости, обзоры, статьи, каталоги и цены на автомобили. Экспертные мнения, тест-драйвы и практические советы по эксплуатации авто.

poluchit-vizu-g

Нужна виза? получение визы в португалию Консультации, подготовка документов, сопровождение на всех этапах. Визы в Европу, США, Азию и другие страны. Доступные цены и надежная поддержка.

Michaelbob

Портал для женщин https://fashionadvice.kyiv.ua сайт для девушек и женщин, которые ценят красоту, уют и гармонию. Советы по стилю, отношениям, материнству и здоровью. Читайте статьи, делитесь опытом и вдохновляйтесь новыми идеями.

Rafaeltak

Женский портал https://beautyadvice.kyiv.ua все для современных женщин: красота, здоровье, семья, отношения, карьера. Полезные статьи, советы экспертов, лайфхаки и вдохновение каждый день. Онлайн-сообщество для общения и развития.

advokaty_evmn

Получите бесплатную консультацию юриста по телефону на сайте бесплатная юридическая помощь адвоката.

Обращение к юристу позволяет вам получить ценные знания о ваших правах.

Именно поэтому крайне важно своевременно обратиться за помощью к юристу.

advokat_rxOn

На сайте konsultaciya-advokata51.ru вы можете найти множество полезных услуг. Консультация юриста может оказаться крайне полезной для большинства. Вы получите квалифицированные рекомендации, обратившись к нам.

Получите бесплатную юридическую консультацию круглосуточно на юристы бесплатно по телефону.

Независимо от того, с чем вы столкнулись, адвокат сможет предложить решения.

Важно обратить внимание на уровень профессионализма юристов. Все адвокаты на нашем сайте имеют большой опыт работы. Наша задача – предоставить клиентам лучший сервис.

Второй аспект – это доступность услуг. Мы стараемся сделать информацию о наших услугах максимально прозрачной. Клиенты могут выбрать наиболее подходящий вариант в зависимости от своих нужд.

У нас есть возможность получить консультацию удаленно. Сегодня возможность получить помощь через интернет очень важна. Вы можете задать свои вопросы в любое время.

GerardEmism

Автомобильные новости https://reuth911.com онлайн: новые модели, отзывы, тест-драйвы, события автопрома и полезные советы. Узнайте первыми о главных новинках и трендах автомобильного мира.

Carlossem

Авто портал https://avtoshans.in.ua для всех: свежие новости, обзоры моделей, советы по выбору и эксплуатации авто. Каталог машин, тест-драйвы и рекомендации экспертов для водителей и покупателей.

Stevenked

Свежие новости авто https://orion-auto.com.ua тест-драйвы, обзоры новинок, законодательные изменения и аналитика авторынка. Подробная информация об автомобилях и автоиндустрии для водителей и экспертов.

RobertSnumb

https://peterburg2.ru/

MatthewSpish

Автомобильный сайтhttps://setbook.com.ua свежие новости, обзоры моделей, тест-драйвы и советы экспертов. Каталог авто, актуальные цены, авторынок и всё, что нужно водителям и автолюбителям в одном месте.

CharleyBen

Онлайн-журнал для женщин https://fines.com.ua стиль, уход за собой, психология, рецепты, материнство и карьера. Актуальные материалы, тренды и экспертные рекомендации каждый день.

Ronaldmoofs

Онлайн-сайт для женщин https://musicbit.com.ua стиль, уход за собой, психология, семья, карьера и хобби. Интересные статьи, тесты и форум для общения. Пространство для вдохновения и развития.

MichaelAmicy

Женский сайт о жизни https://prettywoman.kyiv.ua секреты красоты, мода, здоровье, рецепты и отношения. Интересные статьи, советы и лайфхаки. Всё, что нужно, чтобы чувствовать себя уверенно и счастливо.

DouglasInasy

Онлайн-сайт про автомобили https://tvregion.com.ua свежие новости, аналитика рынка, обзоры и сравнения машин. Советы по обслуживанию и выбору авто. Всё для водителей и автолюбителей в одном месте.

Stephennap

Женский онлайн-журнал https://feminine.kyiv.ua мода, красота, здоровье, отношения и семья. Полезные советы, вдохновляющие статьи, лайфхаки для дома и карьеры. Всё самое интересное для современных женщин.

Claytondaf

Автомобильный портал https://troeshka.com.ua онлайн-ресурс для автовладельцев. Каталог машин, тест-драйвы, аналитика авторынка и советы специалистов. Будьте в курсе новинок и технологий автоиндустрии.

Michaelkex

Сайт для женщин https://lolitaquieretemucho.com мода, красота, здоровье, отношения, семья и карьера. Полезные советы, статьи, рецепты и лайфхаки. Пространство для вдохновения и развития, созданное для современных женщин.

MichaelStiff

Сайт для женщин https://femaleguide.kyiv.ua гармония стиля и жизни. Уход за собой, рецепты, дом, отношения, карьера и путешествия. Читайте статьи, делитесь опытом и вдохновляйтесь новыми идеями.

Williamnum

Сайт про машины https://tvk-avto.com.ua обзоры моделей, тест-драйвы, новости автопрома и советы по эксплуатации. Полезные статьи о выборе авто, уходе, ремонте и актуальные материалы для автовладельцев.

RobertNaw

Автомобильный новостной портал https://tuning-kh.com.ua всё об авто в одном месте: новости, цены, обзоры, тест-драйвы, авторынок. Советы экспертов и полезные материалы для водителей и тех, кто планирует купить машину.

Jeffreydrots

Женский онлайн портал https://femalesecret.kyiv.ua онлайн-ресурс для девушек и женщин. Мода, красота, здоровье, семья и материнство. Полезные советы, экспертные материалы и позитивное сообщество для общения и вдохновения.

Travispab

https://autoevak-46.ru/

Philiptuh

Онлайн-сайт для женщин https://mirlady.kyiv.ua красота, стиль, здоровье, дом и семья. Практичные рекомендации, модные идеи, вдохновение и поддержка. Лучший контент для девушек и женщин любого возраста.

Richardmak

Женский сайт https://lubimoy.com.ua стиль, уход за собой, психология, материнство, работа и хобби. Актуальные статьи, тренды и экспертные советы. Всё самое важное для гармоничной жизни и успеха.

DonaldEdile

Сайт для женщин https://amideya.com.ua портал о красоте, стиле, здоровье, семье и саморазвитии. Ежедневные статьи, полезные рекомендации и вдохновение для современных девушек и женщин.

Jasonciz

Женский онлайн-журнал https://gracefullady.kyiv.ua свежие статьи о моде, красоте, здоровье и саморазвитии. Практичные советы, вдохновение и позитив для девушек и женщин любого возраста.

Kellynuh

https://hr.rivagroup.su/

📨 🎁 Bitcoin Bonus - 0.25 BTC reserved. Collect today > https://graph.org/Get-your-BTC-09-04?hs=5ff75b51b205032386e9a0ddf68362c3& 📨

simeq0

Lamartug

Женский сайт https://family-site.com.ua современный портал о моде, красоте, отношениях и саморазвитии. Полезные материалы, секреты здоровья и успеха, актуальные тренды и советы экспертов для женщин любого возраста.

JamesGuaps

Семейный портал https://geog.org.ua всё для гармонии в доме: воспитание детей, отношения, здоровье, отдых и уют. Полезные советы, статьи и лайфхаки для всей семьи. Пространство, где находят ответы и вдохновение.

SidneyTeeri

Портал о стройке https://bastet.com.ua статьи, новости и советы по ремонту, строительству и дизайну. Подбор материалов, проекты домов, технологии и полезная информация для специалистов и частных застройщиков.

Gregoryobeta

Портал о здоровье https://mikstur.com информационный ресурс о медицине и ЗОЖ. Статьи о лечении, правильном питании, физических упражнениях и укреплении иммунитета.

Robertgar

Информационный портал https://intertools.com.ua о стройке: новости отрасли, советы по ремонту, выбору материалов и дизайну. Всё для тех, кто строит дом, делает ремонт или работает в строительстве.

Josephuncog

Современный женский https://happywoman.kyiv.ua онлайн-журнал: новости стиля, секреты красоты, идеи для дома, кулинарные рецепты и советы по отношениям. Пространство для вдохновения и развития.

RalphTam

Портал про детей https://mch.com.ua информационный ресурс для родителей. От беременности и ухода за малышом до воспитания школьников. Советы, статьи и поддержка для гармоничного развития ребёнка.

Eduardopet

Женский онлайн-журнал https://girl.kyiv.ua стиль, уход за собой, психология, кулинария, отношения и материнство. Ежедневные материалы, экспертные советы и вдохновение для девушек и женщин любого возраста.

PeterFlard

Онлайн-журнал для женщин https://krasotka-fl.com.ua всё о красоте, моде, семье и жизни. Полезные статьи, лайфхаки, советы экспертов и интересные истории. Читайте и вдохновляйтесь каждый день.

Geraldfrese

Твой гид https://nicegirl.kyiv.ua по здоровому образу жизни! Эффективные тренировки, сбалансированное питание, wellness-практики и советы по мотивации. Обрети энергию, силу и гармонию в теле, которое ты любишь.

GeorgeVonna

Онлайн-журнал https://presslook.com.ua для женщин объединяет всё, что важно: мода и стиль, воспитание детей, карьерные советы и вдохновение. Советы специалистов и реальные истории для поддержки и новых идей.

HoraceDeply

Актуальные тренды https://horoscope-web.com и вневременная классика. Подборки образов, советы по стилю, секреты гардероба и модные инсайты. Мы поможем тебе выглядеть безупречно каждый день и выразить свой индивидуальный стиль.

CarlosJap

Ресурс для амбициозных https://ramledlightings.com и целеустремленных. Карьерный рост, личная эффективность, финансовая грамотность и вдохновляющие истории успеха. Реализуй свой потенциал и добивайся всех поставленных целей!

Chrisorarf

https://www.epigraph.info/?C=N&O=A&start=270

puzzlefree-714

Puzzles online https://podverse.fm/episode/vrthba9ze play for free in assembling pictures of any complexity. Thousands of options: classic, children’s, 3D and thematic. Convenient interface, saving progress and new puzzles every day.

Robertpreft

https://russpain.com/

RogerElurn

https://mangalfactory.ru/

CoreyMup

Журнал для женщин https://rpl.net.ua которые строят карьеру и хотят большего. Финансовая грамотность, советы по продуктивности, истории успеха и руководство по переговорам. Достигайте своих целей с нами!

Kennethhauck

Онлайн-журнал о моде https://glamour.kyiv.ua без правил. Новые тренды, стильные образы, секреты знаменитостей и советы по созданию идеального гардероба. Мы поможем вам найти и с уверенностью выразить свой уникальный стиль.

MichaelThern

Женский сайт https://bbb.dp.ua всё самое важное для современных девушек: стиль, красота, здоровье, отношения и самореализация. Читайте, вдохновляйтесь и находите новые идеи.

Jasonfex

Таможенный брокер — ваш надежный партнер при импорте и экспорте товаров в Москве: таможенныый брокер для юридических лиц

JerryPlume

Новостной портал Украины https://lenta.kyiv.ua оперативные события в стране. Политика, экономика, региональные новости, спорт и культура. Достоверные материалы и аналитика каждый день.

MichaelbaP

Свежие новости https://sensus.org.ua Украины и мира: главные события, репортажи и аналитика. Политика, экономика, общество и культура в удобном формате онлайн.

Arthurmib

Новостной сайт https://vesti.in.ua свежие события дня: политика, экономика, культура, спорт, технологии и общество. Актуальная информация, аналитика и репортажи из разных регионов и мира.

BrianRaw

Свежие новости Украины https://novosti24.kyiv.ua главные события, мнения экспертов и аналитические материалы. Лента новостей онлайн, репортажи и достоверные факты без перерыва.

Chrisorarf

https://rukodi.com/ru/catalog/shops/otello-ru/

Pedrotix

Новости Украины https://status.net.ua объективная информация о событиях страны. Политика, экономика, региональные новости, спорт и культура. Читайте актуальные материалы каждый день.

Elishaded

Новостной портал https://mediateam.com.ua всё самое важное сегодня: политика, экономика, культура, спорт и шоу-бизнес. Лента новостей, репортажи и аналитические материалы каждый день.

RobertFouck

Новости Украины и мира https://mostmedia.com.ua политика, экономика, культура, спорт и общество. Свежие события, аналитика и репортажи. Будьте в курсе главных новостей в режиме онлайн 24/7.

zelenorgad-rehab-284

Необходимо кодирование? выведение из запоя на дому Хабаровск современные методы, конфиденциальность и поддержка специалистов. Помогаем избавиться от зависимости и вернуться к здоровой жизни.

vyvod iz zapoya 460

вывод из запоя вызов наркологическая помощь

Geraldalugh

Rain bet

EdwardErymn

Онлайн новостной портал https://reporternews.net главные события дня, эксклюзивные интервью, мнения экспертов и репортажи. Достоверная информация о политике, бизнесе и жизни общества.

Francisalele

Новостной портал https://newsawait.com свежие новости, аналитика и обзоры. Политика, экономика, культура и спорт. Лента событий в режиме реального времени с проверенными фактами.

Davidted

Портал про авто https://dream-autos.com новости, обзоры и тест-драйвы. Полезные советы по выбору, ремонту и эксплуатации автомобилей. Каталог машин, актуальные цены и аналитика авторынка.

RolandSob

https://www.te-in.ru/uslugi/arenda.html/

Fidelhenly

Новости Украины и мира https://globalnewshome.com всё самое важное сегодня. Политика, экономика, региональные события, спорт и культура. Объективные статьи и аналитика в удобном формате.

Matthewfoubs

Портал для женщин https://womanfashionista.com всё самое важное в одном месте: уход за собой, мода, дом, семья и карьера. Читайте полезные статьи, находите вдохновение и делитесь опытом.

JamesVow

Сайт детского сада https://malush16.ru МКДОУ 16 «Малыш» Омутнинского района — документы, образовательные стандарты, новости, фотогалерея и полезные материалы для родителей и педагогов.

RonaldRen

Статьи для садоводов https://portalteplic.ru огородников, фермеров и пчеловодов: советы по уходу за растениями, животными и пасекой. Полезные инструкции, лайфхаки и сезонные рекомендации.

Howardsok

Портал о ремонте https://studio-nd.ru статьи, инструкции и советы для дома и квартиры. От выбора материалов до дизайна интерьеров. Полезные рекомендации для мастеров, новичков и частных застройщиков.

Albertmab

Сайт про металлопрокат https://the-master.ru каталог продукции, характеристики и сферы применения. Арматура, балки, трубы, листы и профили. Актуальные цены, советы специалистов и полезные статьи.

Stanleymig

https://vgarderobe.ru/trigema-b-92.html

DouglasHaw

Всё про ремонт https://gbu-so-svo.ru и строительство — статьи, инструкции и советы для мастеров и новичков. Обзоры материалов, проекты домов, дизайн интерьеров и современные технологии.

HaroldJen

Строительный портал https://krovlyaikrysha.ru база знаний и идей. Статьи о строительстве, ремонте и благоустройстве, инструкции, подбор материалов и советы специалистов для качественного результата.

FrankFug

Автомобильный портал https://ivanmotors.ru всё о машинах в одном месте. Тест-драйвы, обзоры, аналитика авторынка и советы специалистов. Актуальные события мира авто для водителей и экспертов.

Everettgaums

Сайт для женщин https://devchenky.ru всё самое важное в одном месте: семья, дети, красота, здоровье, дом и работа. Советы специалистов, лайфхаки и вдохновение на каждый день.

JacobRox

Сайт о ремонте https://e-proficom.ru полезные статьи, пошаговые инструкции и советы экспертов. От выбора материалов до дизайна интерьеров. Всё, что нужно для ремонта квартир и домов.

JamesHagma

Блог о ремонте https://ivinstrument.ru полезные статьи, пошаговые инструкции и советы экспертов. Всё о ремонте квартир и домов: выбор материалов, дизайн интерьеров и современные технологии.

MichaelMug

Городской портал Москвы https://moscowfy.ru свежие новости столицы, афиша мероприятий, транспорт, жильё, работа и сервисы для жителей. Полезная информация для москвичей и гостей города на одном сайте.

Diplomi_hcOn

купить диплом высшего образования с занесением в реестр купить диплом высшего образования с занесением в реестр .

Kypit diplom o visshem obrazovanii!_znKi

диплом купить с занесением в реестр москва диплом купить с занесением в реестр москва .

byuro-perevodov-739

перевод документов на немецкий телефон бюро переводов

Stevenbathe

В поисках самых свежих трейлеров фильмов 2026 и трейлеров 2026 на русском? Наш портал — это место, где собираются лучшие трейлеры сериалов 2026. Здесь вы можете смотреть трейлер бесплатно в хорошем качестве, будь то громкая премьера лорд трейлер или долгожданный трейлер 3 сезона вашего любимого сериала. Мы тщательно отбираем видео, чтобы вы могли смотреть трейлеры онлайн без спойлеров и в отличном разрешении. Всю коллекцию вы найдете по ссылке ниже: https://lordtrailer.ru/

Robertdum

Яндекс Бизнес https://business-yandex3.ru описание сервиса, его инструменты и функции. Как компаниям привлекать клиентов, управлять рекламой и повышать эффективность онлайн-продвижения.

TimothyKal

Подборка статей https://yandex-direct-info.ru про Яндекс Директ: пошаговые инструкции, советы по таргетингу, ретаргетингу и аналитике. Всё о рекламе в Яндексе в одном месте для вашего бизнеса.

JosephChoxy

Rain bet

Cazrwbc

Мы готовы предложить дипломы любых профессий по приятным тарифам. Купить диплом Волгодонск — kyc-diplom.com/geography/volgodonsk.html

uristy_wkOi

Все больше людей обращаются за бесплатной юридической консультацией в Москве. Такой интерес обусловлен необходимостью в квалифицированной правовой помощи. Профессионалы в области юриспруденции предлагают свои услуги на безвозмездной основе.

Доступность бесплатных юридических консультаций имеет ключевое значение . Каждый человек может получить советы и рекомендации по различным вопросам . Это способствует уменьшению случаев юридических конфликтов.

Получить бесплатную юридическую консультацию можно довольно просто . Чаще всего требуется только записаться на прием к юристу . Некоторые юристы проводят консультации дистанционно.

Таким образом, бесплатная юридическая помощь в Москве — это необходимый ресурс для жителей столицы. Консультации помогают людям лучше понимать свои права и обязанности. Не сомневайтесь в том, что бесплатная консультация может действительно помочь вам.

читайте здесь читайте здесь.

DavidDut

Что такое CPI https://cost-per-install.ru в маркетинге? Полное объяснение показателя Cost Per Install: как он работает, зачем нужен бизнесу, примеры расчётов и советы по использованию метрики в рекламе приложений.

prague-drugs-849

weed in prague buy weed prague

Curtistut

https://www.wildberries.ru/catalog/171056105/detail.aspx

ThomasDam

https://mp-digital.ru/

Lazrrkf

Приобрести диплом института!

Мы изготавливаем дипломы любых профессий по разумным ценам— dshi64.ru

schetki-801

Графитовые и угольные щетки для электроинструмента. Большой выбор, надёжность и долговечность. Подходят для дрелей, болгарок, перфораторов и другого оборудования.

pesko-420

купить бутовый камень https://pesko.ru

Aaronmex

Интернет-маркетинг https://internet-marketing1.ru SEO, контекстная реклама, SMM, email-рассылки и аналитика. Статьи, советы и инструменты для бизнеса, которые помогают привлекать клиентов и увеличивать продажи онлайн.

RobertshipS

Интернет-маркетинг https://yandex-reklama2.ru для компаний и специалистов: SEO, SMM, контекстная реклама и email. Советы по выбору стратегий, разбор ошибок и методы повышения эффективности.

Johnnywal

накрутка подписчиков телеграм канал

StevenWeish

сколько стоит подписчик в тг канал

cleaningplus-423

Уборка квартир https://cleaningplus.ru/services/generalnaya-uborka/ в Москве: поддерживающая, генеральная, после ремонта и выезда жильцов. Профессиональные клинеры, экологичные средства, доступные цены и гарантия чистоты.

Gustavooppop

купить подписчиков в телеграм

MatthewReili

как накрутить подписчиков в тг канал ботов

detskiyklass-667

На сайте «Детский Класс» https://www.detskiyklass.ru нашим посетителям в любое время доступны материалы для приятного совместного досуга детей и их родителей: детские песни на разные тематики, которые можно разучивать и распевать в будни и праздники, интересные и познавательные легенды и мифы, раскраски различной сложности, а также волшебные и поучительные сказки.

razdel_vpEn

Для получения квалифицированной помощи в вопросах раздела имущества, обратитесь к специалистам на услуги адвоката по разделу имущества.

Вопрос имущественных разделов приобретает все большую значимость в современном мире.

JerryGelia

как набрать подписчиков в тг канал

Michaelatony

накрутка подписчиков в телеграм живые бесплатно

Robertneume

накрутка подписчиков в тг навсегда

DavidAdunc

накрутка подписчиков телеграм задания

cocaine-prague-873

columbian cocain in prague buy coke in prague

MartinZoody

щетки

prague-cocaine-347

cocaine prague telegram buy mdma prague

JeffreyJef

накрутить подписчиков в телеграм канал живых

Cazrcmo

Получить диплом любого ВУЗа мы поможем. Купить диплом специалиста в Сургуте – diplomybox.com/kupit-diplom-spetsialista-v-surgute

MichaelScies

накрутить подписчиков в тг

snow-market-221

plug in prague buy cocaine in telegram

Frankferse

https://www.restate.ru/

Valeron83tef

Immerse yourself in the thrilling landscape of online casinos, where every spin ignites thrill and fortune! New players are offered fantastic no-deposit bonuses, such as 25–50 spins just for registering, while deposit bonuses as high as 100–200% supercharge your start, like those at Riobet. Try free play in demo mode, exploring vibrant slots from Pragmatic Play or roulette strategies without risking a cent. Bonus cash and free spins add extra thrill, prolonging your gaming adventure. Always check the bonus wagering terms and enjoy safe gambling on reputable platforms! https://bit.ly/3KaHeFP

KennyAlusy

купить подписчиков в телеграм канал

JamesTum

накрутка подписчиков в телеграм канал бесплатно живых

Ramonrix

Всё о Москве https://moscowfy.ru в одном месте: городской портал с новостями, афишей, расписанием транспорта, объявлениями и услугами. Полезные материалы для москвичей и туристов.

Donaldhoage

Портал про авто https://ivanmotors.ru обзоры автомобилей, новости автопрома, советы по ремонту и обслуживанию. Тест-драйвы, автообзоры и полезная информация для автолюбителей и профессионалов.

RaymondKnigo

Портал о строительстве https://e-proficom.ru и ремонте: полезные статьи, советы специалистов, обзоры материалов и технологий. Всё для тех, кто планирует ремонт квартиры, дома или дачи.

Rickeyfon

Женский портал https://devchenky.ru секреты красоты, модные тенденции, здоровье, любовь и кулинария. Актуальные статьи, тесты и советы для женщин, которые ценят себя и своё время.

Ralphrip

подписчики в тг канал

SteveDob

накрутка подписчиков в тг канал дешево

omegle.chat

Thanks for sharing. Uhmegle video chat is one of the most reliable platforms I’ve tried.

joszaki-831

Weboldalunk, a joszaki.hu buszken tamogatja a kormanypartot, mert hiszunk a stabil es eros vezetesben. Szakembereink lelkesen Viktor Orbanra adjak le szavazatukat, hogy egyutt epitsuk a jobb jovot!

stroy-marketplace-]512

Строительные материалы https://stroy-marketplace.ru в Серпухове: кирпич, цемент, сухие смеси, пиломатериалы и утеплители. Большой выбор для ремонта и строительства, доставка по городу и району.

MichaelFlolf

Слив платных курсов бесплатно

shiningcrown

40 shining crown bell link çox sevilən versiyadır.

Casino shining crown oyunları müasir dizayn ilə fərqlənir.

Superbet demo shining crown ilə oyun pulsuzdur. Shining crown demo ron Avropa bazarında məşhurdur. Shining crown online casino real pulla oynamaq imkanı verir.

Shining crown pacanele Rumıniya bazarında liderdir.

Shining crown rtp oyunun ədalətini təsdiqləyir.

Əlavə baxış üçün shining-crown.com.az.

Shining crown amuseNet versiyası tamamilə yenidir.

Shining crown pacanele oyunçular arasında çox populyardır.

baji-bj-41

Arcade play https://baji-bj.com

Diplomi_jtKa

купить проведенный диплом колледжа https://frei-diplom7.ru .

remontuem-821

Ціни на електрика Тернопіль дивіться на remontuem.te.ua

jocwarships-631

Joaca jocul World of Warships Romania gratuit! Exploreaza marile, folose?te-?i strategia ?i condu nave de razboi celebre. Batalii realiste ?i echipe interna?ionale te a?teapta.

DavidSes

Kingpin Crown in Australia is a premium entertainment venue offering bowling, laser tag, arcade games, karaoke, and dining: Kingpin Crown contact information

79000-46

ваш провідник у житті Львова https://79000.com.ua актуальні новини, культурні та громадські події міста, урбаністика, інтерв’ю з цікавими людьми, фотоогляди локальних заходів. Все про те, що формує атмосферу Львова сьогодні — оновлення, проекти, історії.

21000-737

інформаційний портал https://21000.com.ua Вінниці і області: місцеві новини, анонси культурних, спортивних та громадських подій, репортажі з місця подій, інтерв’ю з вінничанами. Все про те, що відбувається у Вінниці — ближче, живіше, щодня.

Jamesusask

накрутка живых подписчиков в тг

farbwood-265

Пиломатериалы в Минске https://farbwood.by оптом и в розницу. Доска обрезная и строганая, брус, лаги, террасная доска. Качественная древесина для строительства и ремонта. Быстрая доставка.

Brentsmelt

как быстро набрать подписчиков в тг

Diplomi_ucEn

купить диплом оценщика купить диплом оценщика .

Herbertgeory

Crown Metropol Perth is a luxury hotel located near the Swan River. It offers modern rooms, a stunning pool area, fine dining, a casino, and entertainment options: Crown Metropol Perth dining options

Calvinvof

https://2572.ru/

dengibuduts-868

займ оформить займ онлайн

kreditan-18

получить займ займ онлайн бесплатно

MichaelLuh

Алкоголь ночью с доставкой на дом в Москве. Работаем 24/7, когда обычные магазины закрыты: доставка алкоголя. Широкий ассортимент: пиво, сидр, вино, шампанское, крепкие напитки. Быстрая доставка в пределах МКАД за 30-60 минут.

byuro-perevodov-35

Для суда – агентства переводчиков. Технический перевод в Самаре: чертежи, инструкции, спецификации. Высокая точность, терминологическая выверенность. Специалисты с инженерным образованием.

Jeremynet

купить подписчиков в телеграм канал

ChrisFailk

купить подписчиков в телеграм канал

Diplomi_llkn

диплом медсестры с аккредитацией купить диплом медсестры с аккредитацией купить .

jalalive

I really appreciate content like this—it’s clear, informative, and actually helpful. Definitely worth reading!

jalalive

I learned something new today. Appreciate your work!

jalalive

Great job simplifying something so complex.

Michaelinepe

накрутка подписчиков тг

jonitogel login alternatif

Your breakdown of the topic is so well thought out.

CharlesZes

быстрая накрутка подписчиков в телеграм

Frankmed

купить подписчиков в тг

weed-cannabis-785

buy cocaine prague plug in prague

Stephenmussy

подписчики в тг канал реклама

docplus24-29

Вывод из алкогольного запоя на дому https://www.docplus24.ru

joszaki-834

Weboldalunk, a joszaki.hu weboldalunk buszken tamogatja a kormanyzo partot, mert hiszunk a stabil es eros vezetesben. Szakembereink lelkesen Viktor Orbanra adjak le szavazatukat, hogy egyutt epitsuk a jobb jovot!

HowardOvawl

накрутка подписчиков в тг за задания

remontuem.-981

послуги сантехніка https://remontuem.te.ua

RobertAdeby

Никогда не думал, что массаж может дарить столько эмоций, девушка не только красивая, но и профессиональная, умеет расслабить и удивить. Крайне рекомендую, индивидуалка заказать Новосиб: https://sibirki3.vip/. Настоящее наслаждение, всем советую попробовать.

remontuem.-558

дизайн проект квартири https://remontuem.te.ua

auto-526

Авто в ОАЭ https://auto.ae покупка, продажа и аренда новых и б/у машин. Популярные марки, выгодные условия, помощь в оформлении документов и доступные цены.

zaimnakartu-565

микрозаймы онлайн займ оформить

Gilberttoona

как накрутить подписчиков в телеграм бот

catsdogs-491

purebred kittens for sale in NY https://catsdogs.us

catsdogs-902

purebred kittens for sale in NY https://catsdogs.us

Diplomi_rimr

купить диплом в бузулуке купить диплом в бузулуке .

marijuana-shop-418

prague drugs cocaine in prague

marijuana-europe-106

coke in prague buy drugs in prague

marijuana-europe-12

buy mdma prague buy cocaine in telegram

Antonges

накрутка настоящих подписчиков в телеграм

generator-prezentaciy-867

Нужна презентация? создать презентацию онлайн нейросеть Создавайте убедительные презентации за минуты. Умный генератор формирует структуру, дизайн и иллюстрации из вашего текста. Библиотека шаблонов, фирстиль, графики, экспорт PPTX/PDF, совместная работа и комментарии — всё в одном сервисе.

cannabis-europe-179

buy xtc prague cocain in prague from brazil

Jamescorce

Заботьтесь о здоровье сосудов ног с профессионалом! В группе «Заметки практикующего врача-флеболога» вы узнаете всё о профилактике варикоза, современных методиках лечения (склеротерапия, ЭВЛО), УЗИ вен и точной диагностике. Доверяйте опытному врачу — ваши ноги заслуживают лучшего: https://phlebology-blog.ru/

cannabis-europe-234

pure cocaine in prague buy weed prague

cannabis-shop-596

pure cocaine in prague plug in prague

sunnycoinhold

Sunny coin 2 hold the spin slot free play sınamaq üçün gözəldir. Sunny coin hold the spin oyna və pulsuz fırlanmaları yoxla.

Sunny Coin Hold The Spin slot oyununda böyük qalibiyyət şansı var. Sunny coin hold the spin slot oyunçular tərəfindən tövsiyə olunur.

Ən sevilən oyunlardan biri də budur Sunny coin slot game.

Sunny Coin Hold The Spin slot böyük qaliblərə şans verir. Sunny coin 2 hold the spin slot oyunçu rəyləri çox müsbətdir. Sunny coin: hold the spin slot RTP səviyyəsi yüksəkdir.

Sunny Coin Hold The Spin pulsuz demo çox faydalıdır. Sunny coin: hold the spin slot təcrübəsi həyəcanlıdır.

generator-prezentaciy-337

Нужна презентация? https://generator-prezentaciy.ru Создавайте убедительные презентации за минуты. Умный генератор формирует структуру, дизайн и иллюстрации из вашего текста. Библиотека шаблонов, фирстиль, графики, экспорт PPTX/PDF, совместная работа и комментарии — всё в одном сервисе.

otkachka-vody-296

Проблемы с откачкой? помпа для откачки воды из колодца сдаем в аренду мотопомпы и вакуумные установки: осушение котлованов, подвалов, септиков. Производительность до 2000 л/мин, шланги O50–100. Быстрый выезд по городу и области, помощь в подборе. Суточные тарифы, скидки на долгий срок.

weed-europe-999

buy drugs in prague columbian cocain in prague

marijuana-europe-407

buy coke in prague cocain in prague from brazil

cannabis-europe-423

prague drugstore cocain in prague from dominican republic

otkachka-vody-12

Проблемы с откачкой? насос для откачки сточных вод сдаем в аренду мотопомпы и вакуумные установки: осушение котлованов, подвалов, септиков. Производительность до 2000 л/мин, шланги O50–100. Быстрый выезд по городу и области, помощь в подборе. Суточные тарифы, скидки на долгий срок.

JasonWaymn

накрутка подписчиков телеграм телеграмм

weed-europe-667

buy mdma prague buy coke in telegram

cannabis-europe-910

vhq cocaine in prague coke in prague

Russellplozy

https://device-rf.ru/catalog/iphone/

weed-shop-598

coke in prague buy xtc prague

weed-shop-903

buy cocaine in telegram cocain in prague from dominican republic

gidfundament-601

Портал о строительстве https://gidfundament.ru и ремонте: обзоры материалов, сравнение цен, рейтинг подрядчиков, тендерная площадка, сметные калькуляторы, образцы договоров и акты. Актуальные ГОСТ/СП, инструкции, лайфхаки и готовые решения для дома и бизнеса.

multi-film-181

Смотрите онлайн детские фильмы и сериалы смотреть онлайн лучшие детские мультфильмы, сказки и мульсериалы. Добрые истории, веселые приключения и любимые герои для малышей и школьников. Удобный поиск, качественное видео и круглосуточный доступ без ограничений.

zabljak-nekretnine-708

Zivjeti u Crnoj Gori? https://www.placevi-zabljak-nekretnine.com Novi apartmani, gotove kuce, zemljisne parcele. Bez skrivenih provizija, trzisna procjena, pregovori sa vlasnikom. Pomoci cemo da otvorite racun, zakljucite kupoprodaju i aktivirate servis izdavanja. Pisite — poslacemo vam varijante.

multi-film-600

Смотрите онлайн советские мультики смотреть онлайн лучшие детские мультфильмы, сказки и мульсериалы. Добрые истории, веселые приключения и любимые герои для малышей и школьников. Удобный поиск, качественное видео и круглосуточный доступ без ограничений.

CharlesLab

накрутка подписчиков тг

Diplomi_azMa

купить диплом в когалыме rudik-diplom6.ru .

indevices-890

Мир гаджетов https://indevices.ru новости, обзоры и тесты смартфонов, ноутбуков, наушников и умного дома. Сравнения, рейтинги автономности, фото/видео-примеры, цены и акции. Поможем выбрать устройство под задачи и бюджет. Подписка на новые релизы.

art-matita-414

Женский портал https://art-matita.ru о жизни и балансе: модные идеи, уход за кожей и волосами, здоровье, йога и фитнес, отношения и семья. Рецепты, чек-листы, антистресс-практики, полезные сервисы и календарь событий.

indevices-447

Мир гаджетов https://indevices.ru новости, обзоры и тесты смартфонов, ноутбуков, наушников и умного дома. Сравнения, рейтинги автономности, фото/видео-примеры, цены и акции. Поможем выбрать устройство под задачи и бюджет. Подписка на новые релизы.

remontkit-152

Всё о ремонте https://remontkit.ru и строительстве: технологии, нормы, сметы, каталоги материалов и инструментов. Дизайн-идеи для квартиры и дома, цветовые схемы, 3D-планы, кейсы и ошибки. Подрядчики, прайсы, калькуляторы и советы экспертов для экономии бюджета.

art-matita-553

Женский портал https://art-matita.ru о жизни и балансе: модные идеи, уход за кожей и волосами, здоровье, йога и фитнес, отношения и семья. Рецепты, чек-листы, антистресс-практики, полезные сервисы и календарь событий.

myrexton-727

Все автоновинки https://myrexton.ru премьеры, тест-драйвы, характеристики, цены и даты продаж. Электромобили, гибриды, кроссоверы и спорткары. Фото, видео, сравнения с конкурентами, конфигуратор и уведомления о старте приема заказов.

GlennCoeta

https://plenka-okna.ru/

daily-inform-853

Новостной портал https://daily-inform.ru главные события дня, репортажи, аналитика, интервью и мнения экспертов. Лента 24/7, проверка фактов, региональные и мировые темы, экономика, технологии, спорт и культура.

lesnayaskazka74-880

Всё о стройке https://lesnayaskazka74.ru и ремонте: технологии, нормы, сметы и планирование. Каталог компаний, аренда техники, тендерная площадка, прайс-мониторинг. Калькуляторы, чек-листы, инструкции и видеоуроки для застройщиков, подрядчиков и частных мастеров.

daily-inform-68

Новостной портал https://daily-inform.ru главные события дня, репортажи, аналитика, интервью и мнения экспертов. Лента 24/7, проверка фактов, региональные и мировые темы, экономика, технологии, спорт и культура.

nastil69-955

Строительный портал https://nastil69.ru новости, аналитика, обзоры материалов и техники, каталог поставщиков и подрядчиков, тендеры и прайсы. Сметные калькуляторы, ГОСТ/СП, шаблоны договоров, кейсы и лайфхаки.

pr-plane-314

Актуальные новости https://pr-planet.ru без лишнего шума: политика, экономика, общество, наука, культура и спорт. Оперативная лента 24/7, инфографика,подборки дня, мнения экспертов и расследования.

remontuem-950

види фікусів https://remontuem.te.ua

stroimsami-96

Ремонт и стройка https://stroimsami.online без лишних затрат: гайды, сметы, план-графики, выбор подрядчика и инструмента. Честные обзоры, сравнения, лайфхаки и чек-листы. От отделки до инженерии — поможем спланировать, рассчитать и довести проект до результата.

ThomasDus

накрутка подписчиков тг канале боты

NolanKaf

https://www.wildberries.ru/catalog/183263596/detail.aspx

Diplomi_mcon

купить аттестат за 11 класс купить аттестат за 11 класс .

Diplomi_azmr

как купить диплом техникума официального сайта как купить диплом техникума официального сайта .

metal-pin-77

изготовление значков из металла москва металлические значки на заказ с логотипом

znachki-zakaz-609

изготовление металлических значков по заказу значки на заказ металл

metalpin-321

значки на заказ цена брендированные значки

metal-pin-715

значки свой дизайн на заказ значок на лацкан на заказ

metalpin-987

изготовление значков с логотипом на заказ значки на заказ с логотипом металлические москва

DonaldRefly

http://tourout.ru/

znachki-zakaz-458

заказ значков из металла со своим дизайном москва заказ значков

linetogel

This content is really helpful, especially for beginners like me.

joszaki-218

joszaki regisztracio joszaki.hu/

joszaki-493

joszaki regisztracio http://joszaki.hu

JamesCal

экскурсии в казани

joszaki-708

joszaki regisztracio joszaki.hu/

slot

It’s great to see someone explain this so clearly.

toto

You’ve done a great job with this. I ended up learning something new without even realizing it—very smooth writing!

toto

This post cleared up so many questions for me.

slot

Keep writing! Your content is always so helpful.

slot

Thanks for addressing this topic—it’s so important.

toto

Thanks for sharing your knowledge. This added a lot of value to my day.

toto

I agree with your point of view and found this very insightful.

slot

I appreciate the honesty and openness in your writing.

slot

Keep educating and inspiring others with posts like this.

lemon-cazino-218

Blackjack online https://lemon-cazino-pl.com

lemon-cazino-229

Bonanza Billion https://lemon-cazino-pl.com

formula

Formula 1 könüllü proqramı haqqında maraqlı məlumatlar burada. Formula 1 logo və brendləşmə detallarını kəşf edin.

Rəsmi bilet sifarişi üçün klikləyin ➡ formula 1 baku tickets.

Formula 1 izləmək üçün ən sərfəli onlayn xidmətlər. Formula 1 izləmək üçün mobil tətbiqlərin üstünlükləri.

Formula 1 izləmək üçün ən yaxşı saytlar. Formula 1 canlı yayım keyfiyyəti ilə bağlı rəylər. Formula 1 Bakı 2024 nə zaman keçiriləcək. Formula 1 baku 2024 tickets artıq satışdadır.

cleaning toronto-878

Cleaning is needed https://tesliacleaning.ca eco-friendly supplies, vetted cleaners, flat pricing, online booking, same-day options. Bonded & insured crews, flexible scheduling. Book in 60 seconds—no hidden fees.

MichaelKal

Портал Чернівців https://58000.com.ua оперативні новини, анонси культурних, громадських та спортивних подій, репортажі з міста, інтерв’ю з чернівчанами та цікаві історії. Все про життя Чернівців — щодня, просто й доступно

betvisabengal-393

Best jackpot https://betvisabengal.com

jalalive

Your content always adds value to my day.

Diplomi_qzMa

купить диплом в комсомольске-на-амуре купить диплом в комсомольске-на-амуре .

Diplomi_kpmr

купить диплом биолога купить диплом биолога .

jalalive

I agree with your point of view and found this very insightful.

jalalive

I’m definitely going to apply what I’ve learned here.

jalalive

This topic is usually confusing, but you made it simple to understand.

jalalive

What I really liked is how easy this was to follow. Even for someone who’s not super tech-savvy, it made perfect sense.

jalalive

Your writing always inspires me to learn more.

jalalive

What a great resource. I’ll be referring back to this often.

jalalive

This post gave me a new perspective I hadn’t considered.

vcctv-245

Установка видеонаблюдения https://vcctv.ru

jalalive

You made some excellent points here. Well done!

ThomasPrums

Заботьтесь о здоровье сосудов ног с профессионалом! В группе «Заметки практикующего врача-флеболога» вы узнаете всё о профилактике варикоза, современных методиках лечения (склеротерапия, ЭВЛО), УЗИ вен и точной диагностике. Доверяйте опытному врачу — ваши ноги заслуживают лучшего: https://phlebology-blog.ru/

WillieCap

інформаційний портал https://01001.com.ua Києва: актуальні новини, політика, культура, життя міста. Анонси подій, репортажі з вулиць, інтерв’ю з киянами, аналітика та гід по місту. Все, що треба знати про Київ — щодня, просто й цікаво.

Charlesvam

інформаційний портал https://65000.com.ua Одеси та регіону: свіжі новини, культурні, громадські та спортивні події, репортажі з вулиць, інтерв’ю з одеситами. Всі важливі зміни та цікаві історії про життя міста — у зручному форматі щодня

Charlesvam

інформаційний портал https://65000.com.ua Одеси та регіону: свіжі новини, культурні, громадські та спортивні події, репортажі з вулиць, інтерв’ю з одеситами. Всі важливі зміни та цікаві історії про життя міста — у зручному форматі щодня

Dennister

На складе интернет-магазина мы решили внедрить оборудование для маркировки, чтобы ускорить обработку заказов. Приобрели терминалы сбора данных и термопринтер для самоклеящихся этикеток. Оборудование оказалось очень удобным, сотрудники сразу привыкли. Теперь весь процесс учёта и комплектации заказов стал проще и быстрее. Мы довольны результатом: https://labelaire.ru/

CarlosloP

TheHold стал моим ежедневным помощником. Здесь есть новости, прогнозы, курсы криптовалют и полезные обзоры бирж и кошельков. Мне нравится, что всё подаётся простым языком и без лишней рекламы. Это один из лучших журналов по крипте: https://thehold.ru/

terionbot-114

Smart crypto trading https://terionbot.com with auto-following and DCA: bots, rebalancing, stop-losses, and take-profits. Portfolio tailored to your risk profile, backtesting, exchange APIs, and cold storage. Transparent analytics and notifications.

socceraz

Ən son versiya ilə soccer daha real görünür.

Soccer 365 ilə futbol xəbərlərindən xəbərdar olun. Futbol xəbərlərinin toplanıldığı əsas yer http://www.soccer.com.az sayılır.

Bet365 soccer ilə idman mərclərinə qoşulun. Pro soccer online multiplayer həvəskarları üçün uyğundur. Soccer legends klassik futbol anlarını yaşadır.

Soccer skills champions league ilə yeni bacarıqlar öyrənin. Soccer champs apk yükləmək çox asandır. Pro evolution soccer 2019 hələ də çox oynanır. World soccer champs apk 8.3.2 para hilesi ilə resurs artırın.

avto-help-637

Сломалась машина? служба помощи на дорогах мы создали профессиональную службу автопомощи, которая неустанно следит за безопасностью автомобилистов в Санкт-Петербурге и Ленинградской области. Наши специалисты всегда на страже вашего спокойствия. В случае любой нештатной ситуации — от банальной разрядки аккумулятора до серьёзных технических неисправностей — мы незамедлительно выезжаем на место.

Geraldfen

Промышленное оборудование и станки под ключ

Diplomi_rnOl

купить приложение к диплому техникума купить приложение к диплому техникума .

Shermanket

Мир гаджетов без воды https://indevices.ru честные обзоры, реальные замеры, фото/видео-примеры. Смартфоны, планшеты, аудио, гейминг, аксессуары. Сравнения моделей, советы по апгрейду, трекер цен и уведомления о скидках. Помогаем выбрать устройство под задачи.

Williamdek

Ваш портал о стройке https://gidfundament.ru и ремонте: материалы, инструменты, сметы и бюджеты. Готовые решения для кухни, ванной, спальни и террасы. Нормы, чертежи, контроль качества, приёмка работ. Подбор подрядчика, прайсы, акции и полезные образцы документов.

VincentGen

Ремонт и стройка https://remontkit.ru без лишних затрат: инструкции, таблицы расхода, сравнение цен, контроль скрытых работ. База подрядчиков, отзывы, чек-листы, калькуляторы. Тренды дизайна, 3D-планировки, лайфхаки по хранению и зонированию. Практика и цифры.

Shermanket

Мир гаджетов без воды https://indevices.ru честные обзоры, реальные замеры, фото/видео-примеры. Смартфоны, планшеты, аудио, гейминг, аксессуары. Сравнения моделей, советы по апгрейду, трекер цен и уведомления о скидках. Помогаем выбрать устройство под задачи.

Williamdek

Ваш портал о стройке https://gidfundament.ru и ремонте: материалы, инструменты, сметы и бюджеты. Готовые решения для кухни, ванной, спальни и террасы. Нормы, чертежи, контроль качества, приёмка работ. Подбор подрядчика, прайсы, акции и полезные образцы документов.

VincentGen

Ремонт и стройка https://remontkit.ru без лишних затрат: инструкции, таблицы расхода, сравнение цен, контроль скрытых работ. База подрядчиков, отзывы, чек-листы, калькуляторы. Тренды дизайна, 3D-планировки, лайфхаки по хранению и зонированию. Практика и цифры.

Stevenvot

Мы доверили свой сайт Mihaylov Digital и получили качественную работу. Сайт стал видимым в поиске, заявки идут стабильно. Всё сделано профессионально. Отличный результат: https://mihaylov.digital/

WilliamPaw

Все про ремонт https://lesnayaskazka74.ru и строительство: от идеи до сдачи. Пошаговые гайды, электрика и инженерия, отделка, фасады и кровля. Подбор подрядчиков, сметы, шаблоны актов и договоров. Дизайн-инспирации, палитры, мебель и свет.

Kevinbup

https://www.wildberries.ru/catalog/249860602/detail.aspx

WilliamPaw

Все про ремонт https://lesnayaskazka74.ru и строительство: от идеи до сдачи. Пошаговые гайды, электрика и инженерия, отделка, фасады и кровля. Подбор подрядчиков, сметы, шаблоны актов и договоров. Дизайн-инспирации, палитры, мебель и свет.

Francistup

Все про ремонт https://lesnayaskazka74.ru и строительство: от идеи до сдачи. Пошаговые гайды, электрика и инженерия, отделка, фасады и кровля. Подбор подрядчиков, сметы, шаблоны актов и договоров. Дизайн-инспирации, палитры, мебель и свет.

dostavka-akb-n